|

|

||

|

||

|

|

||

|

INHALTSVERZEICHNIS_____________________________________________IHM

SD

Introduction

...........................................................................................................................

2

Drive 4 WD

.........................................................................................................................

4

Transmission

.................................................................................................................................

5

Hanging up

.......................................................................................................................

6

Brakes

................................................................................................................................

8

Power steering

.........................................................................................................................

9

Räderund vehicle drive (general

references)

.........................................................................

10

Drive system Viscomatic clutch

...........................................................................

11

Hydraulic control circuit

............................................................................................................

17

Electronic Kontrollanlage

.................................................................................................

22

Funktionsiogik of the system

..................................................................................................

25

Components of the system

....................................................................................................

35

Diagnostics of the system

........................................................................................................

42

Abs system, version for four

drive wheels

................................................................... 43

General description

......................................................................................................

44

Interference logic for the

version 4 WD

........................................................................................

45

Localization components of the

system

.............................................................................

48

Description of function

..........................................................................................................

52

Selbstdiagnose

......................................................................................................................

53

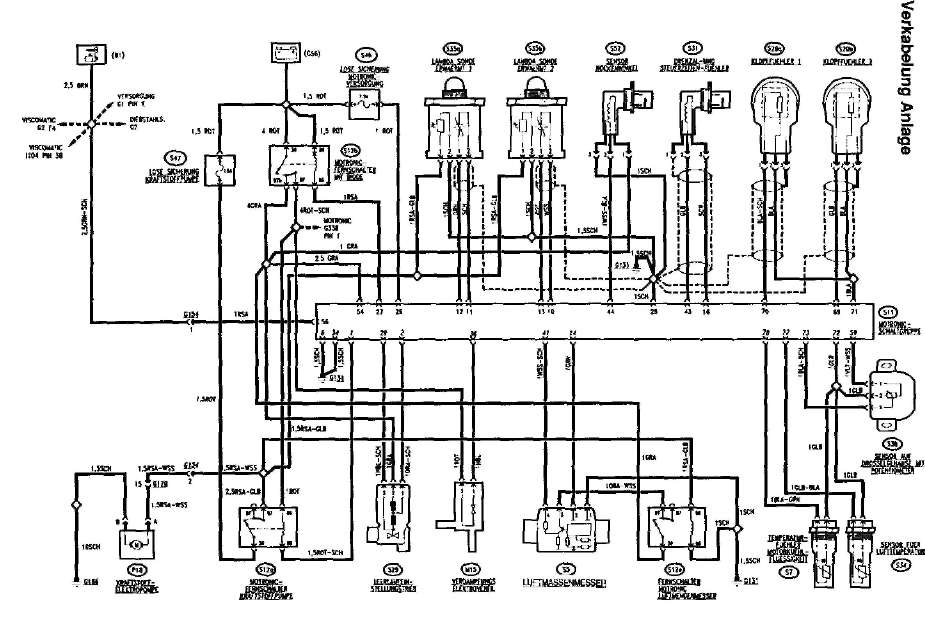

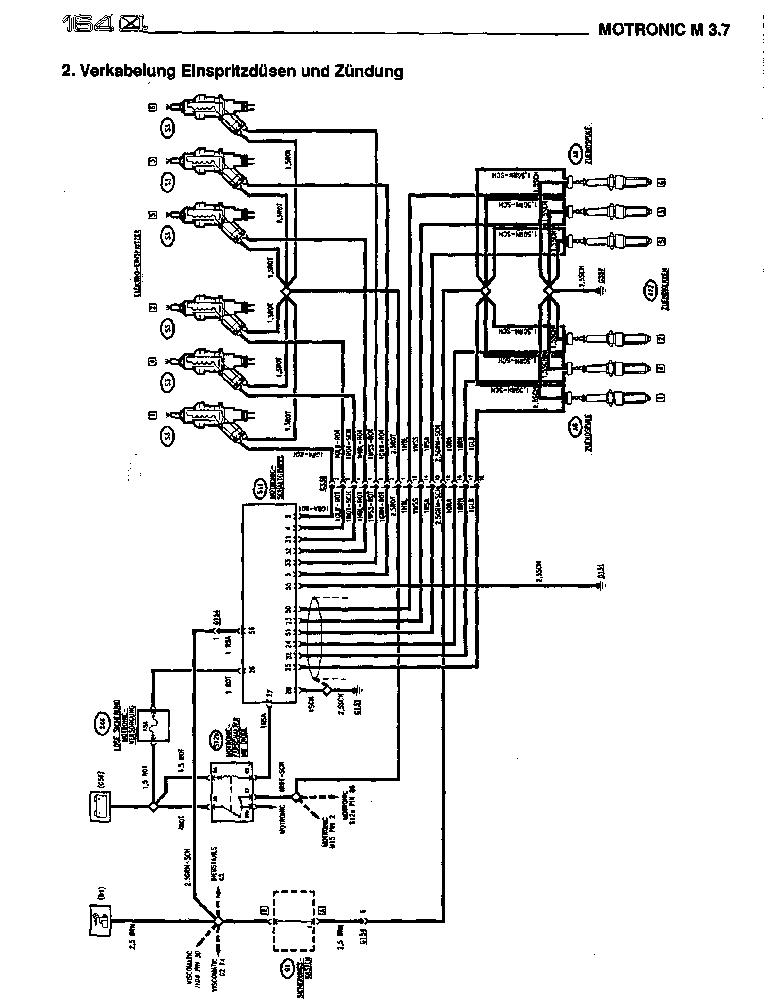

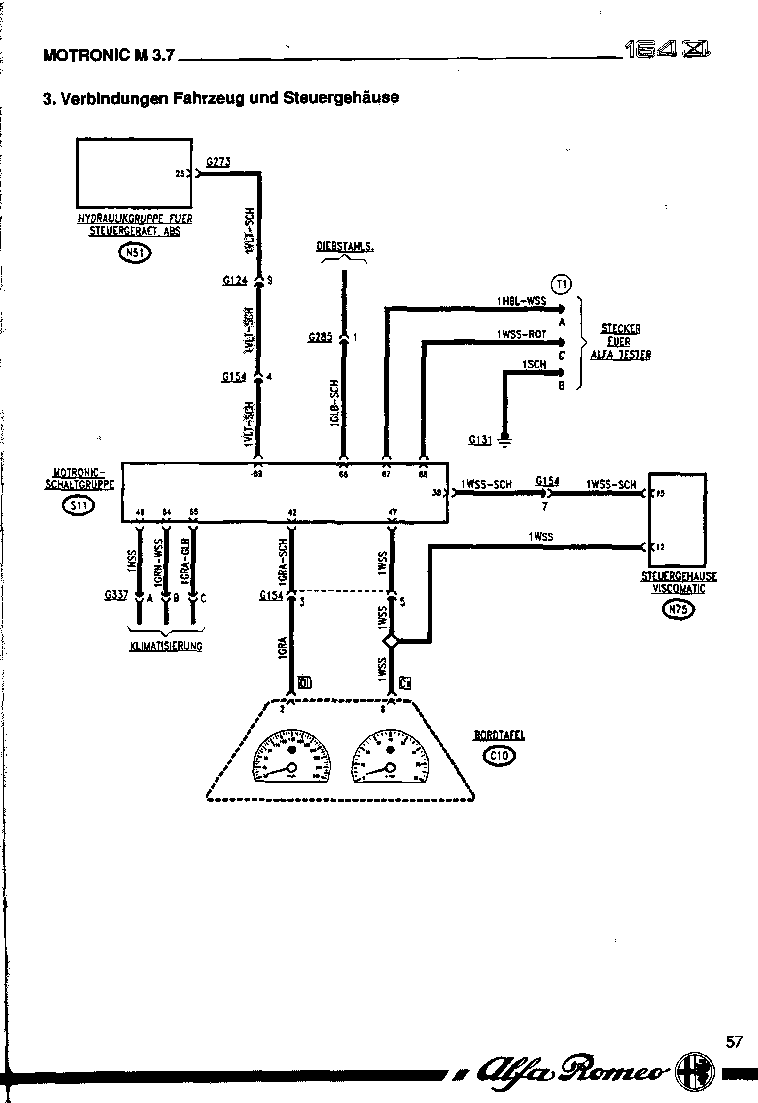

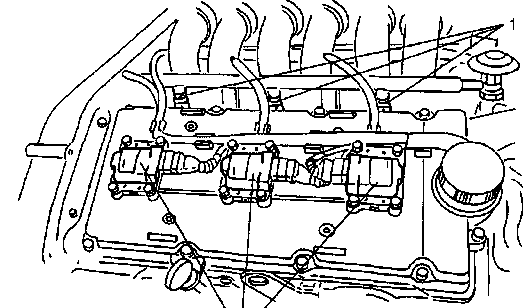

Electronic engine management

Motronic M 3,7 ........................................................

54

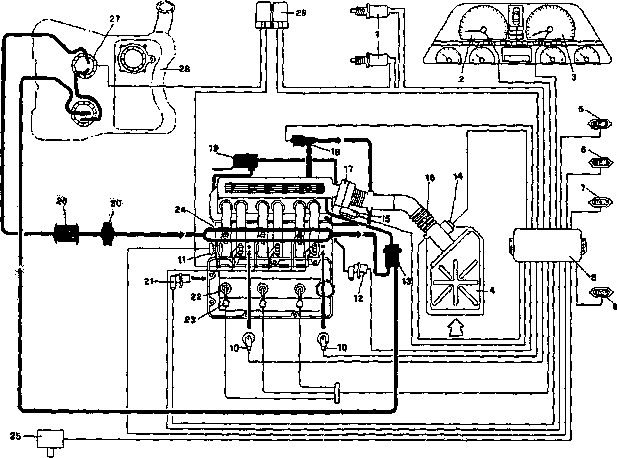

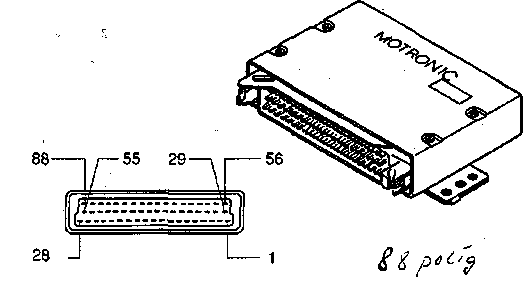

MotronicM3.7

.......................................................................................................................

58

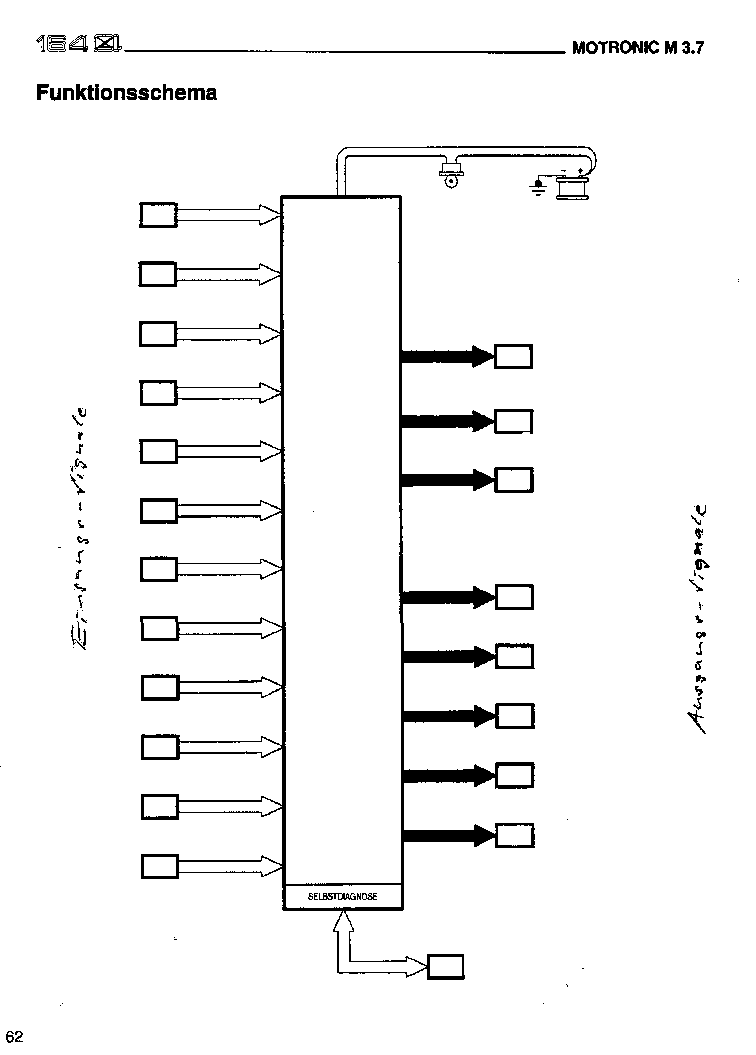

Operation diagramme

...................................................................................................................

62

Electronic steering box

..............................................................................................

64

Components

........................................................................................................................

65

Selbstdiagnose

......................................................................................................................

69

Fuel system circle

...................................................................................................

70

On-board board

..............................................................................................................................

74

Notes/notes

...........................................................................................................

77 |

||

|

|

||

|

|

||

|

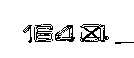

1Bi§

B_________________________________________________EINLEITUNG

Introduction

The available publication

documents the variants and the systems, which were specifically developed

for the 1B^S. They are to be described here and in the detail represented,

thus all necessary information for the general knowledge of the vehicle

and the operational principle of the different plants, systems and above

all the electronic controls be conveyed can. |

||

|

|

||

|

2 |

||

|

|

||

|

|

||||

|

MECHANICAL

GROUPS |

||||

|

|

||||

|

|

|

||

|

|

||||

|

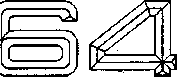

The

all-wheel drive system Viscomatic, which finds with the new ISA BÖL

use, was developed exclusively by the Alfa Rome EO technical

designers in co-operation with Steyr Puch.

With 164

was still continued to improve the characteristics of the all-wheel drive

owing to „the active " drive system,

in which the moment distribution varriert continuously according to the given

logics, depending upon driving

condition (drive torque, guidance angle, driving speed, process between

front axle and rear axle), which are calculated by the electronic steering box VISCOMATIC®.

One

received so an all-wheel drive, which gives new 164 high „driving safety " in

each driving condition and in the most

diverse situations. |

||||

|

|

||||

|

||||

|

|

||||

|

The reached advantages can be

summarized in such a way:

- To limit „active " interference of the system,

which administers the torque

process variable, but continuously, without the travelling

comfort;

- maximum stability when braking, by a

special version of the ABS for 4WD;

- no influence of the drive with driving

along curves, due to the construction;

- high achievements of the entire system, due

to the good quality of the construction;

- A construction, which made possible it

to accomplish an adjustment without

large changes at the past model 164 with 2 drive

wheels. |

||||

|

|

||||

|

||||

|

|

||||

|

|

|||

|

|

MECHANICAL GROUPS |

||

|

|

|||

|

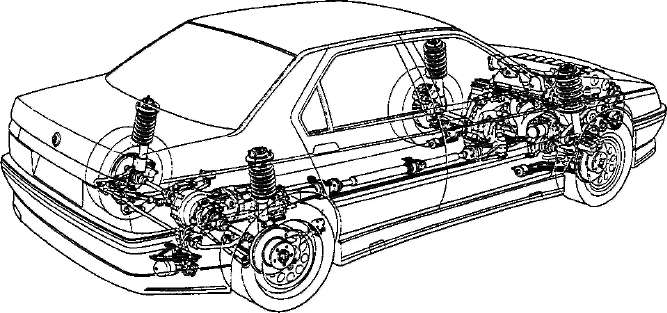

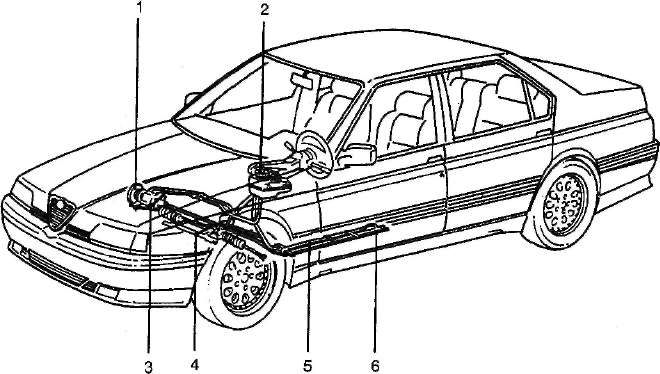

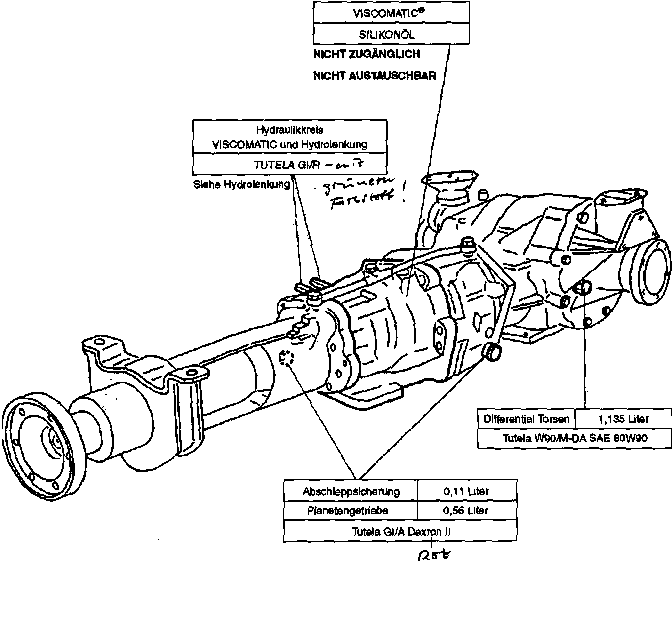

4WD

propelled

The unpublished construction

solution of the drive for *$sk£k the Sl plans a mechanical

TRANSMISSION with 6 COURSES. The allocation of the drive over a

VISCOMATIC^ clutch with ELECTRONIC CONTROL, as well as a Torsen

Diffe

“rential

an~cJer Hinteractrse.

- |

|||

|

|

|||

|

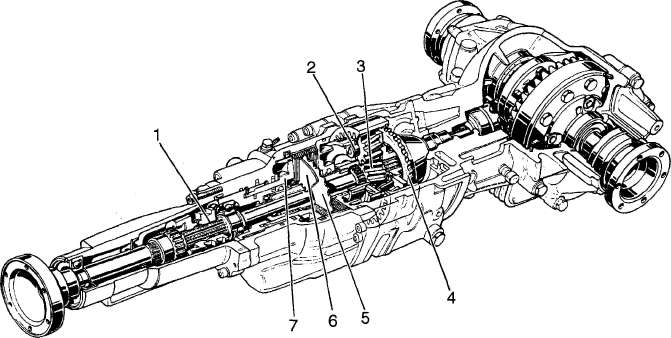

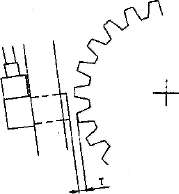

1. Course: 3.769

2. Course: 2.333

3. Course: 1.680

4. Course: 1.290

5. Course: 1.031

6. Course: 0,837 R. Gang: 3.720 |

||

|

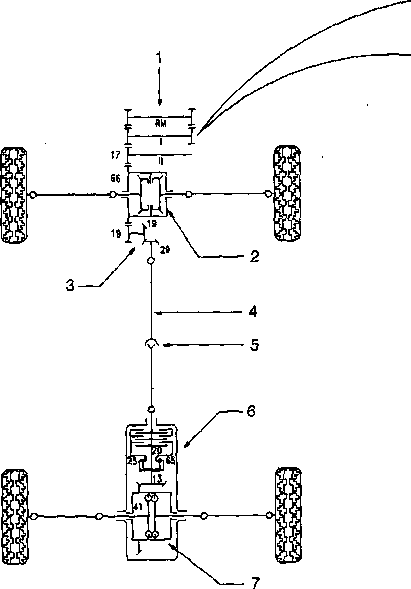

1.

Transmission

2. Front differential

3. Reduction gear

4.

Drive shaft

5. Universal joint

6. Clutch VISCOMATIC®

7. Rear differential

Torsen |

|||

|

|

|||

|

(The numbers indicate the number of teeth of the different

wheel transmissions) |

|||

|

|

|||

|

The

kinematic pattern plans a VISCOMATIC® clutch between the front axle

and the rear axle. The torque between the two wheels is subdivided in

front by a conventional differential, while on the rear axle a gate EN

differential was used, so that the drive in each situation is

maximally used.

Owing

to the special construction of the Torsen it makes this kind

of self-locking that for differential possible, with small adhesion of a Rades,

the drive moment on the wheel with the better road grip too transferred (up to the

quadruple value). |

|||

|

|

|||

|

|

|||

|

MECHANICAL

GROUPS |

.16 |

||

|

|

|||

|

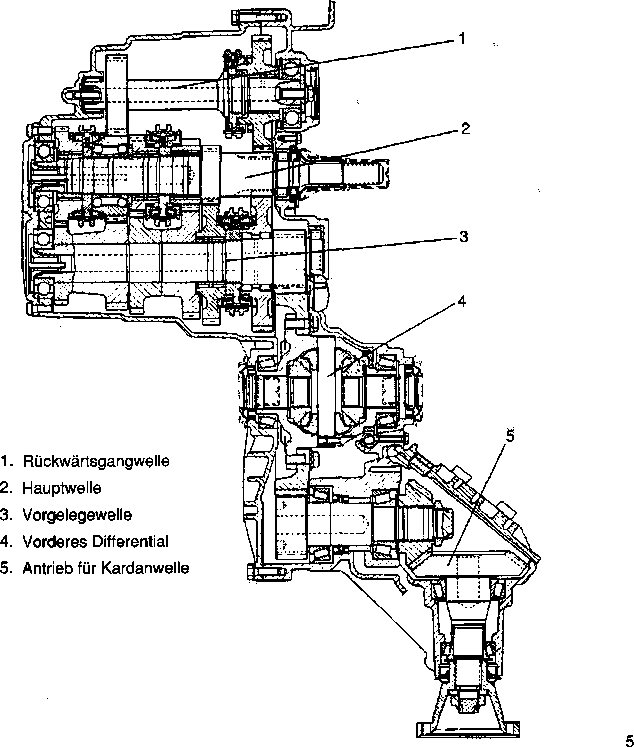

Transmission

With (

a new transmission of the company GET-RISE

UP with 6 courses begun, that a new transmission of the company GET-RISE

UP with 6 courses begun, thataccordingly one

designed, in order to make possible fast accelerations, due to the appropriate gradations of the courses. In

this way the maximum torque of the engine (which is very high)

is, always at all wheels and

in each operating condition available. This results in an unexpected

acceleration behavior for a vehicle of this kind with constructional equipment opposite a

2-Radantrieb. |

|||

|

|

|||

|

The

transmission range contains also the front differential and the drive for

the cardan shaft. |

|||

|

|

|||

|

|||

|

|

|||

|

|||

|

|

|||

|

|

||

|

||

|

|

||

|

Hanging up

The

hanging up were again designed, extensive and complex experiments to keep

accomplished around a maximum

handling and comfort for this 4WD-Fahrzeug. This vote was reached

together with the optimization of the specific operating logics of the

VISCOMATIC clutch, which are

connected in special way with the behavior of the hanging up. |

||

|

|

||

|

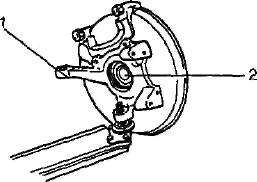

Front suspension

The front

suspension became within the range of the position of the steering arm (1)

on the hub (2) changed. |

||

|

|

||

|

||

|

|

||

|

In addition all points of the

suspension became to the specific sportiven characteristics

the vehicle adapted, thus

high guidance precision was reached.

The

feathers/springs and shock absorber have a special characteristic. In the

shock absorbers are additional

feathers/springs, which intervenes in the delimitation phase as an

anti-centrifuge and an anti-pitch oscillation function. This makes

one possible „softer " measuring of the external feathers/springs for the increase of

the travelling comfort. |

||

|

|

||

|

||

|

|

||

|

The

applied solutions make possible to

adapt the high achievements to the sensitivity of the steering

element, with from-following

stability in curves, even if border situations

are

reached. |

||

|

|

||

|

|

||||

|

MECHANICAL GROUPS |

M |

|||

|

|

||||

|

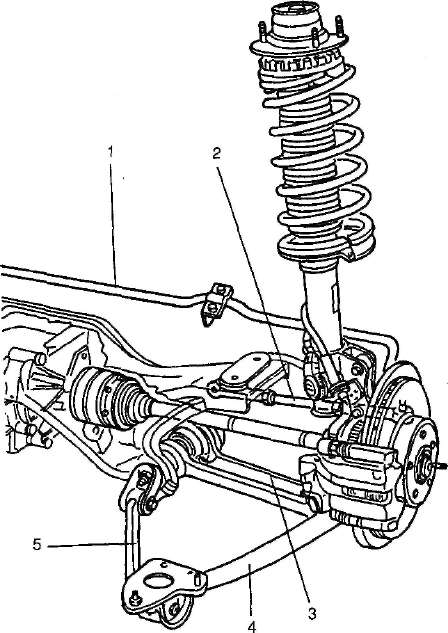

Rear suspension

It was completely again

designed, in order to ensure the demands of the new drive

system.

The new suspension is

characterized by the following:

- A lower wishbone (3), which

takes up the lateral load;

- An upper unreactive

(2);

- A lever (4) and a linkage (5)

in longitudinal direction;

- A stabilizer (1), for the

entire reconciliation of the group.

The elasticity of the system

under transverse loads makes an easy self-steering possible with

stabilizing effect. |

||||

|

|

||||

|

1. Stabilizer

2. Upper unreactive

3. Lower Schwingarm

4. Semi-trailing arm

5. Linkage |

|

|||

|

|

||||

|

7 |

||||

|

|

||||

|

|

|||

|

|

||||

|

|

|||

|

MECHANICAL

GROUPS |

||

|

|

|||

|

Also at

the rear suspension feathers/springs and shock absorbers have specific

measuring and the shock absorbers to

have an internal feather/spring, like the front.

The

applied solutions make as a further improving, and an optimal power transmission at the

rear axle in the course for the steering control possible as also in the thrust.

Hanging up with controlled absorption

The

electronic Kontroilsystem SCS varied in the measuring of the shock

absorbers and is the same system,

which already worked with the other versions 164. The interference logic was adapted to the new

drive system. |

|||

|

|

|||

|

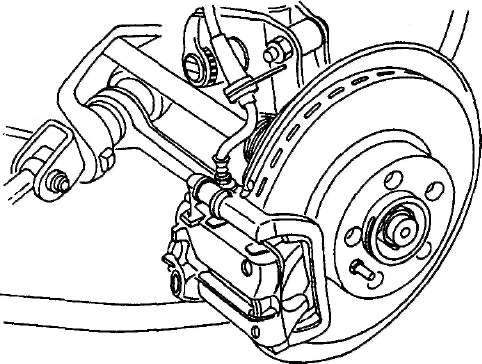

Brakes

The

brake assembly was again developed accordingly for this vehicle and equipped with a specific power steering and ventilated

brake disks.

Due to

the high demanded achievements the brake pliers were again developed, in

order to thus achieve a higher

efficiency. |

|||

|

|

|||

|

|||

|

|

|||

|

|

|||

|

MECHANICAL

GROUPS |

% |

||

|

|

|||

|

Power steering

The

plant of the power steering was adapted to the specific characteristics of

this vehicle. The hydraulic guidance pump - propelled by the Poly V belt

of the crankshaft - consists of two

separated pumps - power steering and Viscomatic -. Both pumps are attached at the same supply cycle. The

steering housing is specific, since in this the guidance sensor is, which belongs to

the VISCOMATIC system. |

|||

|

|

|||

|

|||

|

|

|||

|

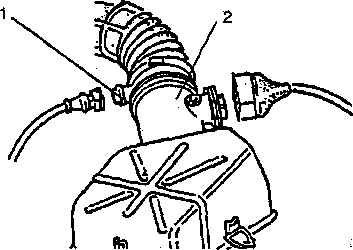

1. Hydraulic guidance pump

2. Header tank |

|||

|

|

|||

|

3.

Zulaufleitungen

4.

Steering housing

5.

Return pipes

6. Inlet and return pipes VISCOMATIC

plant |

|||

|

|

|||

|

|||

|

|

|||

|

|

||

|

1B£1

El_________________________________MECHANISCHE GROUPS

Wheels and vehicle

drive

With

vehicles with all-wheel drive, the automatic work on the wheels and the

vehicle towing are problematic, since the two axles must be

separated before.

With

is

the VISCOMATIC system with an appropriate mechanical is

the VISCOMATIC system with an appropriate mechanicalSystem

equipped that complete switching off makes possible for the VISCOMATIC

clutch. According to turning the engine (ignition off out) after

approximately 4 min. the connection to

the rear axle is separated automatically.

Only

after this time interval is:

- balancing the individual wheels at the

vehicle

- towing the vehicle

possible. |

||

|

|

||

|

10 |

||

|

|

||

|

|

||||||

|

VISCOMATIC |

||||||

|

|

||||||

|

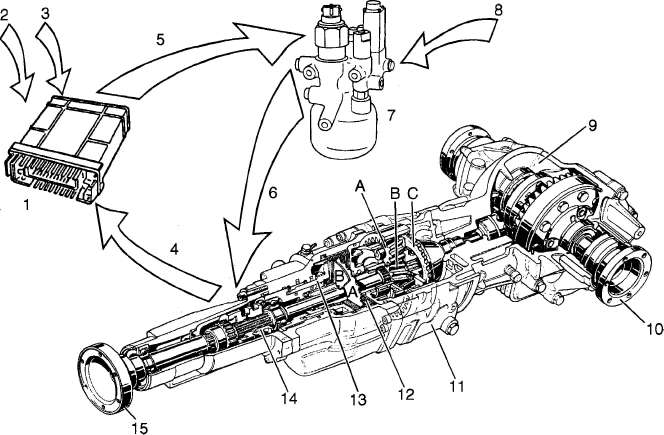

Drive system VISCOMATIC

clutch

To Alfa

Romeo

became between the two axles a

Drehmomentverteiler also became between the two axles a

Drehmomentverteiler alsoelectronic control of type

VISCOMATIC® assigned, as well as a rear differential type Torsen (basic

relationship 4: 1).

With ideal adhesion conditions

of the four wheels the drive is made by the front wheels. When revving the

wheels up at the front axle, the VISCOMATIC plant distributes the drive

torque to the rear axle.

The Kontrollogik takes over the

optimal distribution of the torque, that to the rear axle depending upon

driving condition is transferred (drive torque, vehicle speed, guidance

angle and the slip between in front and in the

back). |

||||||

|

|

||||||

|

||||||

|

|

||||||

|

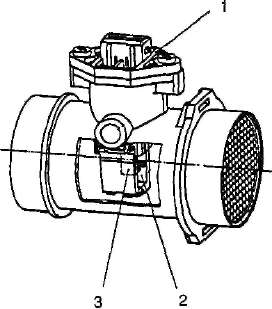

1. |

Electronic steering box control of 9

VISCOMATIC system // ^*W

1Q |

Rear gate EN

differential

Flange for left half

wave

Planetary gear

Group of disk clutch

VISCOMATIC

Hydraulic piston for control

clutch

Towing protection

Flange for drive shaft |

||||

|

2. 3rd

4. 5th 6. 7th 8. |

Signals of the steering box

Motronic '“^0

Signals of the steering box ABS

“'i/M~reLC

Signal position of the hydraulic

piston

Control signal for hydraulic

control block

Supply of the hydraulic

piston

Hydraulic control block with

memory |

11.

12.

13.

14.

15. |

||||

|

Supply hydraulic control block

(of the hydraulic guidance pump) |

||||||

|

11 |

||||||

|

|

||||||

|

|

|||||

|

|

||||||

|

|

||

|

OVER

EU_____________________________________________VISCOMATIC

VISCOMATIC®

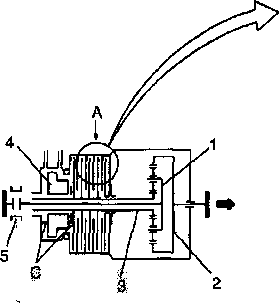

The VISCOMATIC® consists of a

planetary gear and a viscose rayon clutch with hydraulic control. In

addition an appropriate mechanical device makes a switching off for the

power transmission possible, which while towing the vehicle on only one

axle becomes necessary. - _ |

||

|

|

||

|

||

|

|

||

|

1.

Towing protection

2. Planetray gear

3. Sun wheel

4. Internal gear

5. Interior disk

6.

External disk

7.

Piston with hydraulic

control |

||

|

|

||

|

|

|||||||

|

VISCOMATIC |

|||||||

|

|

|||||||

|

ENTRANCE |

|

|

|

||||

|

Mixture silicone oil/air

without pressure

transferred torque

down |

under pressure

transferred torque highly |

||||||

|

EXIT |

|

||||||

|

|

|||||||

|

The torque becomes from the planet pinion cage (1)

transferred to the internal gear (2).

The translation from the planet

pinion cage to the internal gear is possible, if the sun wheel f3) -

connected with the clutch and the brake function - also partly

blockieittst. The more largely the blocking, the more largely is the

transferred torque.

The viscose rayon clutch (A) consists of lamellas and a

mixture of silicone oil and air.

The transmission of the movement

in the viscose rayon clutch is reduced by the inconsistency of the oil,

since the oil with air vesicles enriched itself. By the piston (4) the oil

air mixture rising printing values is suspended, thus reduce the air

vesicles, which approach lamellas and it will thus a higher torque

transferred.

With the loosening of the clutch

by the piston (4) the lamellas are pressed apart with the pressure of

warmed up air and the torque which can be transferred reduce.

Each position of the piston,

steered of an electrical valve and the respective pressure in the

hydraulic system steers thus the torque which can be

transferred. |

|||||||

|

|

|||||||

|

13 |

|||||||

|

|

|||||||

|

|

||||||

|

|

|||||||

|

|

||||

|

VISCOMATIC |

|||

|

|

||||

|

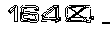

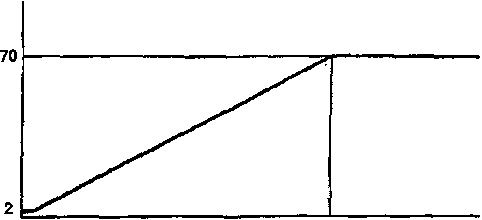

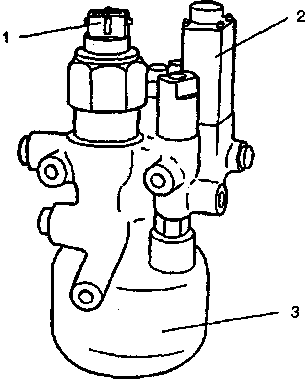

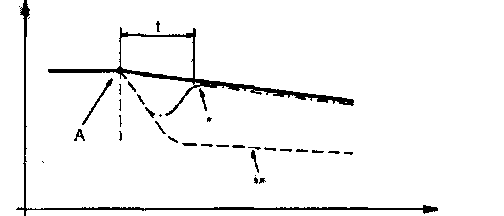

Viscose rayon clutch

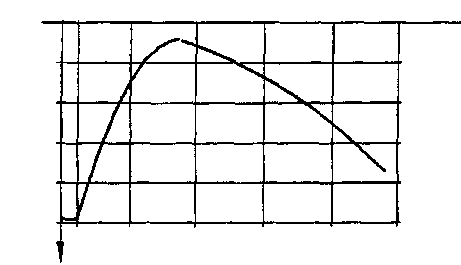

The characteristic of the clutch

(transferred torque M/speed difference on) can vary inside a certain range

(see illustration), that by the condition of the maximum transmission is

limited (HARD) and from that the minimum transmission (SOFT). The system

places the clutch into a certain point of function in the work area and

thus arises the transmission of the necessary torque on the rear

axle. |

||||

|

|

||||

|

Piston position max. |

HARD |

On |

||

|

Piston in resting position |

||||

|

|

||||

|

14 |

||||

|

|

||||

|

|

|||

|

VISCOMATIC |

|

||

|

|

|||

|

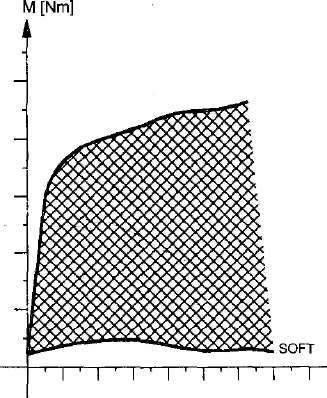

Elimination rear axle

An

appropriate mechanical system (towing protection) makes the complete Auschalten and thus the separation of the

rear axle for the viscose rayon clutch possible.

That is

very important while towing the vehicle on only one axle, since towing with attached axles would damage

the VISCOMATIC clutch.

This

concerns a mechanical device with hydraulic regulation: The clutch {switch

shaft and shift collar) is separated, if the pressure of the tax hydraulic

system of the VISCOMATIC sinks under

a certain level: The interference value varies depending upon

internal friction, temperature

etc.: Indikativer value approx. 20 bar. |

|||

|

|

|||

|

|||

|

|

|||

|

Switched on clutch

switched off clutch

The

pressure (p) exceeds Kraft that the applied pressure (p) over

cry

Feather/spring (m)

and makes a scarf tet Kraft for the

feather/spring possible (m) not and those

ten the

clutch (G).

Clutch (G) is not switched

on. |

|||

|

|

|||

|

REMARK: When

switching the ignition off the hydraulic system needs a certain time (0.5 to 4 minutes), in order to arrive

under 20 bar.

Therefore some minutes wait,

before the vehicle is towed. |

|||

|

|

|||

|

|||

|

|

|||

|

|

||

|

VISCOMATIC |

||

|

|

||

|

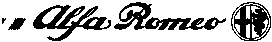

Hinwels

The

transmission system plans the use of 4 different liquids, as represented on the following

pattern: |

||

|

|

||

|

||

|

|

||

|

16 |

||

|

|

||

|

|

|||

|

VISCOMATIC |

|||

|

|

|||

|

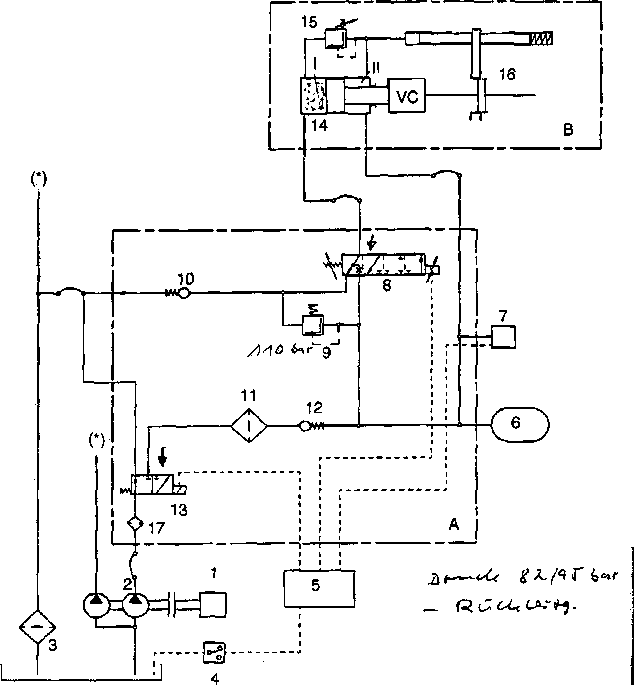

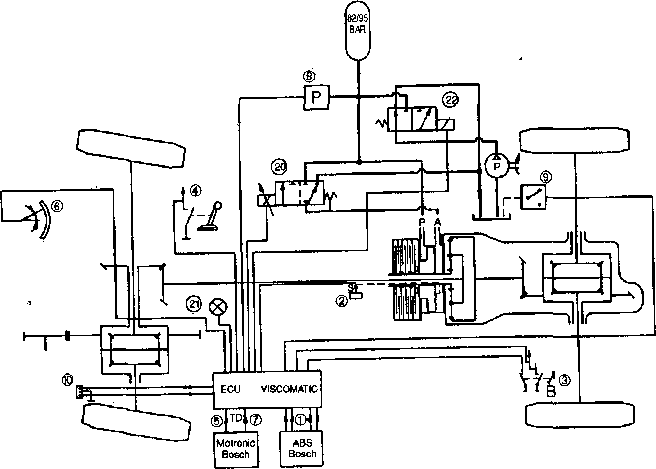

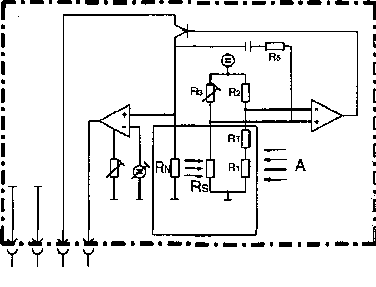

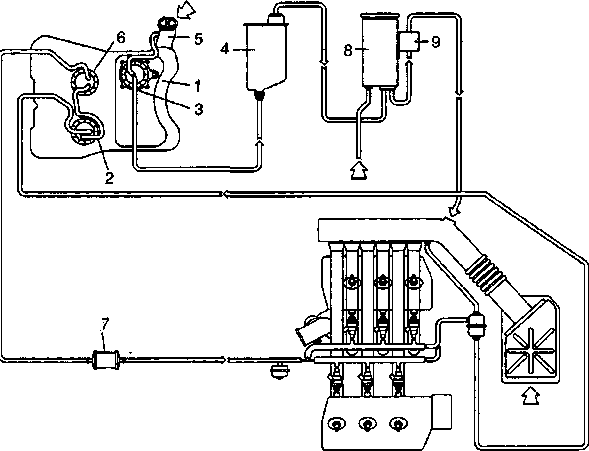

Hydraulic control circuit

A

hydraulic system with high pressure supplies an accumulator, which leads

the necessary liquid quantity with a sufficient pressure to the hydraulic

system. The supply circle is

integrated, and by means of a pump by the crankshaft is propelled

with that the power steering.

This concerns a double pump with 2 different pressure levels for the two

circles:

1. max. 100 bar vane-type pump for the

hydraulic guidance circle and

2. max. 200 bar - piston pump for the

VISCOMATIC circle. |

|||

|

|

|||

|

|||

|

|

|||

|

1. Ausgleichsbehäiter

2.

Double pump

3. Housing power steering

4. Accumulator with hydraulic control block

VISCOMATIC

5. Clutch VISCOMATIC |

|||

|

|

|||

|

17 |

||

|

|||

|

|

|||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Hydraulic pattern |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

A =

hydraulic control block B =

VISCOMATIC clutch

(*) von/zu hydraulic guidance

circle |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

VISCOMATIC |

|

||

|

|

|||

|

Description of function

The

supply pump (2), propelled by the Poly V belt of the engine (1), the liquid leads to the hydraulic guidance plant and to the

hydraulic control block of the VISCOMATIC (A). The header tank (3)

with Filterelement in the oil return the reconciliation of the quantity

varying of the oil, which arises during the enterprise, guarantees due to

the work quantity (of memory) and the

thermal extension: Altogether approx. 400 cm3. The sensor (4) the

electronic steering box informs VISCOMATIC (5) in case of of low

oil level. The electrical valve at the accumulator (13) becomes from the

steering box (5) activated and loads

the memory (6) up, whereby a pressure between 82 and 95 bar of a sensor

(7) is held. The memory (6) - capacity 0.5 dm3 - the necessary

energy for the enterprise of the VISCOMATIC guarantees inside the system;

on the supply line a pressure filter (11) is - filter achievement 20 u.m -

that the whole group before foreign particles protects, which could damage

the valves, as well as a return non-return valve (12) that to the pump

prevents the return flow of the oil; a further auxiliary filter (17)

protects the memory load valve (13). The valve (9) the system protects

against positive pressure and opens the circle at 110 bar. The return

non-return valve (10) return flow prevents into the VISCOMATIC group by

the hydraulic guidance

circle.

The

proportional valve for adjustment (8) steer the VISCOMATIC clutch (B) and

regulate the oil flow in the chamber (I) of the piston (14); the oil

pressure in the chamber (II) constantly by the memory one maintains:

therefore becomes on varying the quantity led into the chamber (I) shifting the piston and thus varying

the stiffness of the clutch reached. The function of the valve follows in the

detail:

A. Valve with a certain electric

current supplies: Liquid quantity to the chamber (I) of the

piston

b: closed valve

C: Discharge the chamber (I) from

the piston to the container - with started engine -

D: Discharge the chamber (I) of

the piston - with turned off engine: It becomes a further

river the oil reservoir in the memory (6) and in the chamber (II) reached,

so that the whole plant is emptied.

|

|||

|

|

|||

|

The

pressure in the chamber (II) switching on of the clutch (towing protection

on 16 controls): If the pressure sinks, scolded the

clutch mechanically the whole group of clutch rear differential out.

The valve

(15) - calibrated on 102 bar - for the automatic exhaust of the plant one

uses (for further details see „exhaust

of the circle "). |

|||

|

|

|||

|

; &g&, &*rw^ |

|||

|

|

|||

|

|

|||||||||||||||||||||||||||||||||||||||

|

VISCOMATIC |

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

Supply pump |

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

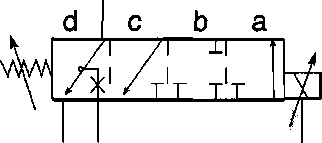

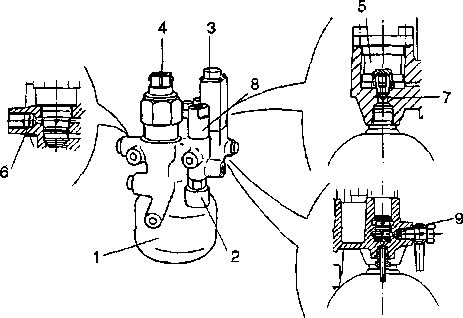

Hydraulic control block

In a

building group all valves and components of the hydraulic system are accommodated for the controlling of the

VISCOMATIC clutch. |

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

1. Accumulator

2.

Pressure sensor

3.

Speicherladeyentil

4. Hydraulics proportional valve

5.

Pressure filter

cartridge

6. Return non-return valve

7.

Return non-return

valve

8. Relief valve

9. Auxiliary filter |

||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

||

|

VISCOMATIC_________________________________________________IBÖ

SSI

Exhaust of the hydraulic

system VISCOMATIC

The

exhaust of the circle is made by

an appropriate valve inside the device,

and is not thus not accessible and not adjustable.

The

exhaust is to be accomplished only with ALFA ROMEO the TESTER: This

procedure plans the start of the

engine, whereby this is brought to 2000 revolutions; then sends a

controlling of the tester a constant river of 450 mA to the proportional

valve and controls according to also the memory load valve,

increases the pressure of the circle over the maximum operating values, whereby

the bleed valve is opened (on 102 bar calibrated) and lets to the

container air collected in the plant to stream out. In the case of

completion of this procedure it is possible to examine with the tester

whether the plant without air

is. |

||

|

|

||

|

||

|

|

||

|

|

||

|

V1SC0MATIC |

||

|

|

||

|

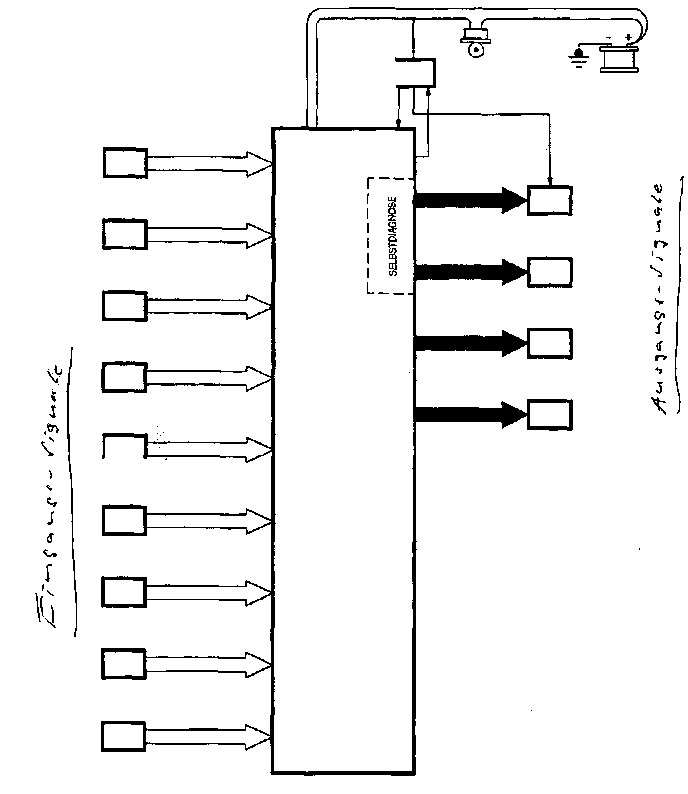

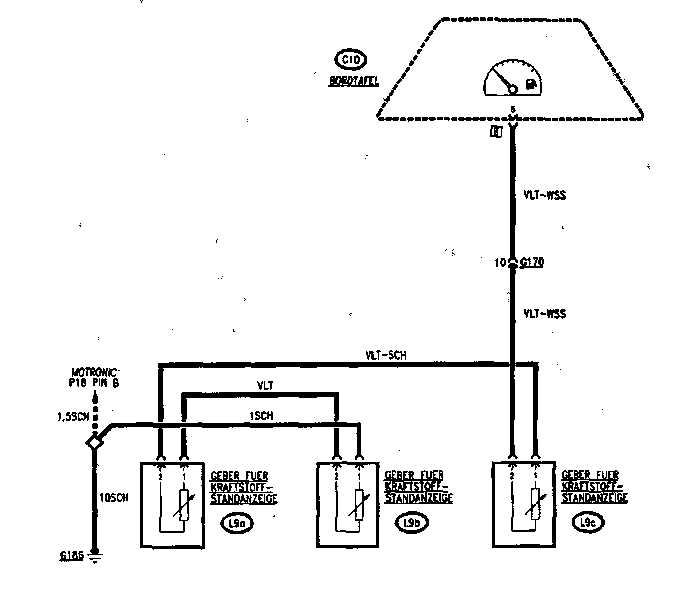

Electronic

Kontrollanlage

The electronic steering

box VISCOMATIC controls „the slip " between the foremost and

rear axle and limits it at certain values, depending upon the

different driving conditions. These conditions are inferred by several

sensors or taken up by other plants (ABS or Motronic). The

steering box steers therefore the valves, which regulate the

function of the viscose rayon clutch. The operation diagramme

points this out schematically: |

||

|

|

||

SAFETY I RELAY

| PRESSURE HYDRAULIC SYSTEM SIGNAL LAMP DISTURBANCE PLUNGER LIFT CLUTCH ANSCHLUSSTECKER ALFA ROMEO

TESTERS GUIDANCE ANGLE HYDRAULIC PROPORTIONAL

VALVE STOOD HYDRAULIC OIL MEMORY LOAD

VALVE STEERING

BOX

VISCOMATIC® ^-■

WHEEL SPEED BUTTERFLY VALVE ANGLE ENGINE NUMBER OF

REVOLUTIONS MANIPULATION

BRAKE SWITCH ON REVERSE

GEAR |

||

|

|

||

|

|

|||

|

VISCOMATIC |

|

||

|

|

|||

Sensors

and Kontroilogistik |

|||

|

|

|||

|

The

Kontrollogistik of the steering box, which steers the hydraulic system of

the VISCOMATIC, plans the

availability of a series of data, which are inferred partly directly by

sensors and are partly

again-processed. In accordance with these parameters the steering box

regulates the electrical valve (20) with a variable river (from 400 to

2300 mA) proportional for the speed of the piston, the connection of the

clutch varied and thus the allocation of the transmission moment on the

rear axle.

The

directly inferred data are the following:

- The number of revolutions of the four wheels.

The four data become from the abs system (1) taken

over.

- The Drehzahi of the engine by the steering box

Motronic (7).

- The opening angle of the butterfly valve (in

the percentage), by the steering box Motronic (5).

- The guidance angle

(6), given by a specific sensor in the steering element

housing.

- The position of the piston (2), whose stroke

from 0 to 5 mm can vary; the position of maximum resetting is recognized, if the

river of the electrical valve (20) is with 900 mA.

- The pressure of the hydraulic system of the

memory, measured of the sensor (8); this pressure is held between 82 and 95 bar by

a memory load valve (22).

- A signal during operation of the brake

(3).

- A signal when switching on of the reverse

gear (4) on.

- Sensor oil level (9). |

|||

|

|

|||

|

|||

|

|

|||

|

|

||

|

1B^1 SO”

_________________________________________________VISCOMATIC

The

system is with a control light (21) and with the possibility for the

diagnosis with the Alfa Romeo tester

(10) equipped.

REMARK:

The function of the steering box is dependently on the voltage level of

the battery, under 9 V scolded

themselves it not.

There are

parameters, which are not inferred directly by the sensors, but by the

steering box in accordance with special logics to be calculated, which are

described as follows:

|

||

|

|

||

|

24 |

||

|

|

||

|

|

|||

|

VISCOMATIC |

1 |

||

|

|

|||

|

Function logic of the

system

The most

important logics are described here, which are regulated by the software of the

steering box, in order to regulate

the allocation of the torque by the clutch. |

|||

|

|

|||

|

Drive torque

The

drive torque at the wheels is calculated by the product of the torque,

which is delivered by the engine for

the entire drive. It is

indicated as percentage of

its maximum value. The torque

delivered by the engine is inferred from the curves of the load diagram,

which is stored in the steering box. Each value of the number of revolutions and

percentage of the butterfly valve opening, correspond to a value of

the torque, which is delivered by

the engine.

The total

drive is calculated against it by

the relationship between engine number of revolutions and number of revolutions of the front

axle. |

|||

|

|

|||

|

DRIVE TORQUE

(%) |

|||

|

|

|||

|

|||

|

|

|||

|

0

1000

2000

3000

4000

5000

6000

7000 |

|||

|

|

|||

|

ENGINE SPEED

(1/min) |

|||

|

|

|||

|

|

||||

|

VISCOMATIC |

|||

|

|

||||

|

Slip between foremost and rear axle

By slip one understands the

proportional difference of the speed of the front axle opposite the rear

axle.

Front axle - rear axle x 100

Slip = speed difference

-------------------------------------------------

Rear axle

In order to be able to have the

value of the slip due to revving the tires up, one must take the kinetic

slip.

This kinematic slip is the

result of the over each other setting of the two conditions:

First is due to the variability

between the turning extent of the tires due to for example wrong printing

values, or different wear condition, unequal tire load, presence of the

spare wheel etc.

The second condition, which

determines the kinematic slip, is the different rotating speed of the

axles, which arises in the curve. The C.I.R. (center of the momentary

turn) shifts depending upon guidance angle, in addition, depending upon

deviation of the tires. |

||||

|

|

||||

|

||||

|

|

||||

|

Deviation of a Rads with tires under a lateral

load. |

||||

|

|

||||

|

This angle results from

different variables, how: Kind of tire, pressure of the tire, trap

coefficient.

In addition it is directly

proportional to the centrifugal energy (square of the radius speed,

guidance radius and measures of the vehicle) and the torque used at the

wheel; it is opposite proportional against it to the vertical load on the

wheel.

The steering box regards only

the kinematic effects and thus only the speed parameters and guidance

angles. |

||||

|

|

||||

|

26 |

||||

|

|

||||

|

|

||||

|

VISCOMATIC |

|

|||

|

|

||||

|

-

With standard speed the speed increase increases the deviation forward.

That calls (see illustration) a

shifting „of the center of the turn " (+) forwards, with from-following reduction of the kinematic

slip. |

||||

|

|

||||

|

DRIVING

DIRECTION |

|||

|

|

||||

|

On

the other hand the situation turned around when backing up: Shifting „the

center of the turn " (+) causes an

increase of the kinematic slip. |

||||

|

|

||||

|

DRIVING

DIRECTION |

|||

|

27 |

||||

|

|

||||

|

|

|||

|

|

||||

|

|

|||

|

VISCOMATIC |

||

|

|

|||

|

There are tables over the normal

trip and over the reverse movement. The kinematic slip is reduced as

described with increase of the deviation (standard speed) and with reverse

movement the slip increases.

The evaluation of the kinematic

slip due to the curve movement is read from the system, and compared with

the stored tables in the program of the steering box - in that the

important data are contained -. |

|||

|

|

|||

|

Positioning the piston

In order to guarantee that the

distribution of the course torque on the two axles is made in shortest

time it is before-shifted, the regulation, as the piston is positioned

depending upon course torque. From this position one proceeds, in order to

make the definite attitude concerning the slip, if this

arises. |

|||

|

|

|||

|

STROKE PISTON (%)

100} |

|||

|

* - TRACTION POWER |

||

|

|

|||

|

In order to guarantee a good

function of the system, for example when fast starting, with which the

taken values of the important parameters close the piston during

pre-setting, other signals are not considered, which would cause

mismatching partial openings of the piston. If the system would consider

for example small guidance angles at low speeds, the piston is opened,

whereby thereby disturbing conditions would arise when

driving. |

|||

|

|

|||

|

28 |

|||

|

|

|||

|

|

||||

|

VISCOMATIC |

||||

|

|

||||

|

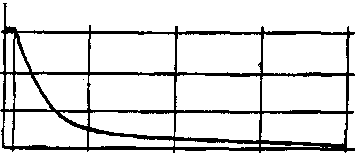

Attitude of the course slip

With special circumstances the

system does not intervene also at important slip values.

For

example a high slip value is certified at low speeds. One avoids in such a way that the attitude of

small measuring errors of the speed and irregularity of the road

surfacing, although small, is affected, which would be important however in this

case.

For the

same reason the certified slip value increases, if the course torque is limited. |

||||

|

|

||||

|

CERTIFIED

SLIP

|

||||

|

|

||||

|

VEHICLE

SPEED |

||||

|

|

||||

|

CERTIFIED

SLIP |

||||

|

|

||||

|

COURSE

TORQUE |

|||

|

|

||||

|

29 |

||||

|

|

||||

|

|

|||

|

|

||||

|

|

|||

|

16 |

VISCOMATIC |

||

|

|

|||

|

Attitude of the transverse slip of the rear axle

The closing differential (Torsen

4: 1) in the rear axle causes that in the curve the internal rear wheel is

loaded with a quadruple higher torque. This wheel tends to revving up,

since in the curve also the vertical load sinks. In this condition the

slip between the two axles to inappropriate way and the piston reduce

tended to open and lead to an allocation of the torque between the two

axles with increase of the average speed of the rear wheels, which brings

driving difficulties with itself. In this case a function intervenes,

which adds itself to the difference between the real slip and the

certified and is lost due to revving the internal rear wheel up. Therefore

the piston remains closed due to the signal by this wheel, whereby the

movability of the vehicle is improved. |

|||

|

|

|||

|

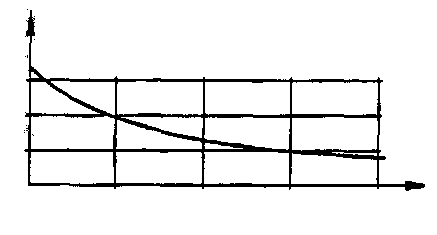

Attitude of the sliding operating slip

With sliding enterprise the

exhaust brake works the vertical load on the rear axle, which can rev up

therefore easily particularly on the front axle, on the other side sinks

in this condition. |

|||

|

|

|||

|

REMARK: If the speed of the rear axle more highly than those

the foremost

axle is, takes the slip negative values.

The certified negative slip at

low speeds is therefore for the same reasons higher, from those, as seen,

at low speeds the course slip is high. At medium speeds the value of the

certified slip is limited, since a good torque value reduces the

Untersteuern (with bad adhesion), which arises in the curve particularly

on the front axle on the rear axle.

At high speeds the threshold

increases strongly, in order to let the exhaust brake affect only the

front axle and to thus guarantee a good driving

stability. |

|||

|

|

|||

|

* - VEHICLE

SPEED |

||

|

|

|||

|

CERTIFIED SLIP (NEGATIVE) |

|||

|

|

|||

|

30 |

|||

|

|

|||

|

|

|||

|

VISCOMATIC |

1 |

||

|

|

|||

|

Attitude when braking

The

system refers to the rear axle. When braking the real speed of the rear axle is not considered, if this by a

delay over 0,24 g is determined. At higher delay values the datum speed

sinks not in accordance with the

real process separates gradually.

The

VISCOMATIC normally intervenes, until the difference between the effective

speed and the delimitation

speed does not exceed a certain threshold value (also

function of the guidance angle: This threshold is limited with low

guidance angles). Above this threshold the VISCOMATIC does not intervene

during braking, except with exceptions, whereby malfunctions with the abs

plant are avoided (for further

details see „brake system ABS 4WD "). |

|||

|

|

|||

|

|

|||

|

CD

r \ 3 |

|||

|

|

|||

|

|

||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

■ |

|||

|

|

|||

|

|

|||||

|

VISCOMATIC |

|||||

|

|

|||||

|

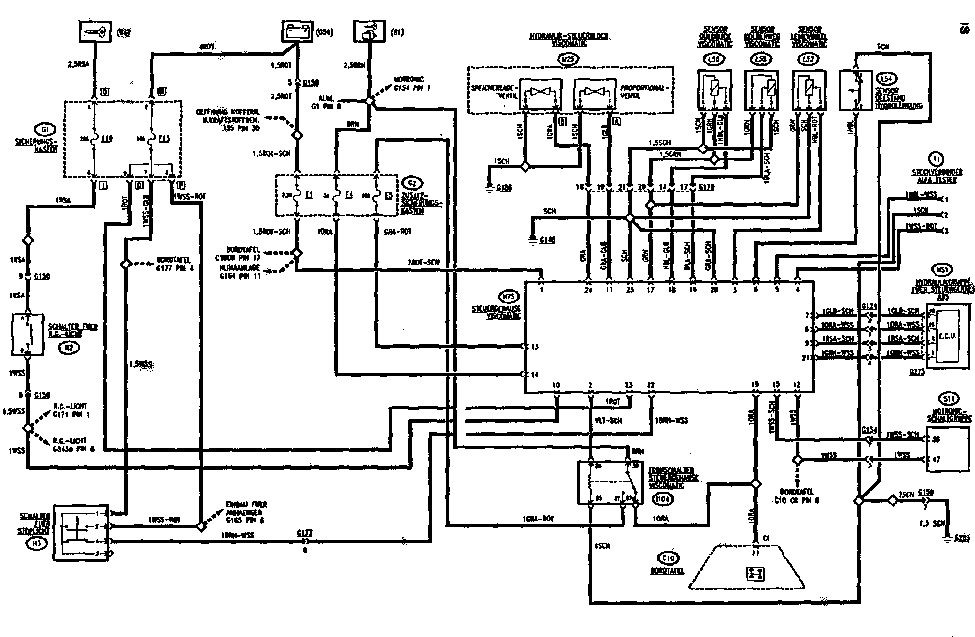

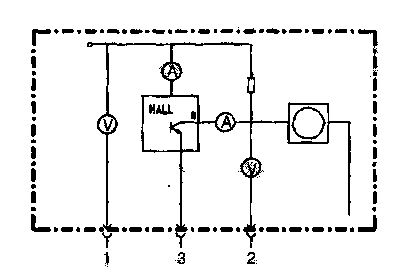

Description of function

The system of the VISCOMATIC is administered by the

controller N 75.

The permanent voltage supply of

the controller is made via the battery, by the protection F1 (7.5 A) -

additional fuse housing G 2 -, on the controller pin

1.

Against the pins rests

20 and 25 of the controller measure. The information

„ignition " comes over the protection F 4 (3 A) - G 2 - on the controller

pin 14.

The main supply for the controller is made over the change

relay 1104. |

|||||

|

|

|||||

|

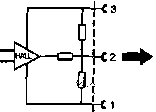

Relay function: no

Fehler>

with Fehler> the

sensors: |

After the info. „ignition " over

pin 14 at the controller, this accomplishes a Eigendiagnose

Relay becomes over the Kl. and

supplies now the controller excites 86 with 12 V via Kl. 30 over Kl. 87,

protection F 5 (10 A) - G 2 - at pin 13 with battery

voltage.

Indicator light becomes of relays

Kl. 87a with tension supplies and shines.

Guidance protractor L 53

1 = 5 V

2 = signal voltage - >

pin 3 Stg

3 = measures

|

||||

|

|

|||||

|

Oil pressure sensor L 56 |

|||||

|

|

|||||

|

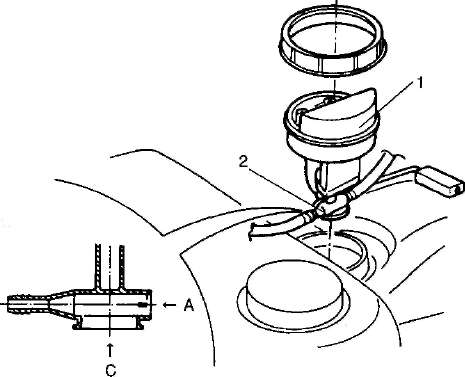

A = measures of B = 5

V

C = signal

voltage |

Pin 18 Stg |

|||

|

|

|||||

|

Sensor plunger lift L 55

Pin 1 = 5 V - ►

Pin 2 = signal voltage - *■

pin 16 Stg

Pin 3 = measures

Sensor oil level L 54

Switch reverse gear: H 2 informs

the controller at pin 10 with 12 V that the reverse gear is

inserted.

Brake pedal switch H 3

1 =12 volt

2 = pedal pressed - *■

pin 23 Stg “h|

4 = pedal not pressed - ► pin 22 Stg

|

|||||

|

|

|||||

|

|

||

|

HM3Ü_________________________________________________VISCOMATIC

Except

of the appropriate sensors, the steering box receives N75 information from

the abs system and Motronic system:

The pins 7.8.9 and 21 of the N75 are connected with the steering box ABS N51, from

which they receive proportional signals for the speed of the 4 wheels; at

the pins 15 and 12 comes against it from the steering box Motronic S11 the signals of the butterfly valve

angle and the engine number of revolutions.

The logic

before shown processes the steering box the control signals of the

actuators, which are controlled

accordingly: From the pin 11 the signal “Duty Cicle” (variable, 250

cycles per second) comes,

which the proportional valve inside the hydraulic control block M25

steers, of the pin 24 comes a

continuous signal 12 V to the controlling (ON OFF) of the memory load valve of the group of

M25.

Pin 4 and 5 for the diagnostic

possibility (plug T1) - line K and L - to the connection with Alfa Romeo the TESTER. Pin 19 12 a V-signal

for the control light of on-board board C10 in case of of stored

disturbances. |

||

|

|

||

|

34 |

||

|

|

||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

VISCOMATIC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

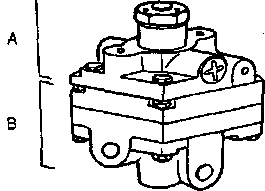

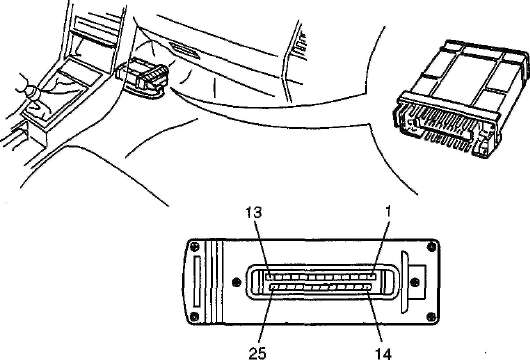

Components of the

system

Electronic steering box

(N75)

It is under the middle

console, in the shown position: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PIN-OUT steering

box:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 V-supply (+15)

Signal

butterfly valve angle (of

Motronic)

Signal

plunger lift

Supply

+ 5 V for the sensors

Signal

pressure hydraulic system

Signal

for signal lamp on-board board (12

V)

Measures of achievement

circles

Signal

speed wheel in front left (of

ABS)

Signal released brake

pedal

(12 V)

Signal

pressed brake pedal (12

V)

Signal

control memory load valve (12V)

Measures of system

circles |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

VISC0MAT1C |

|||

|

|

|||

|

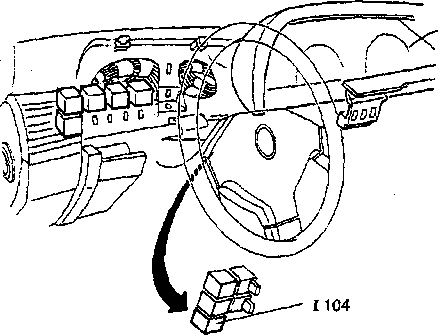

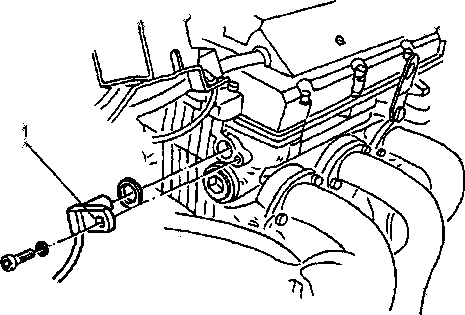

Safety external switch (1104)

The

steering box controls and regulates the supply of the achievement circles

by an appropriate external switch, which interrupts the supply at the

actuators and thus the system switches

off, if it comes to disturbances.

The external switch is on the

right side behind the combination instrument. |

|||

|

|

|||

|

|

||

|

|

|||

|

1104 safety external switches

for steering boxes VISCOMATIC |

|||

|

|

|||

|

|

|||

|

VISCOMATIC |

.1 |

||

|

|

|||

|

Stop light switch (H3)

The same

switch as for is the circle of the stop lights, 2 signals by the

controller is processed: approved and

pressed brake pedal.

Reverse gear switch

(H2)

The same

switch as for is the circle of the backup lights, from which from the

signal of the switched on reverse gear

proceeds.

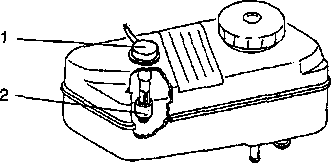

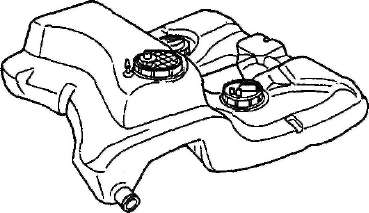

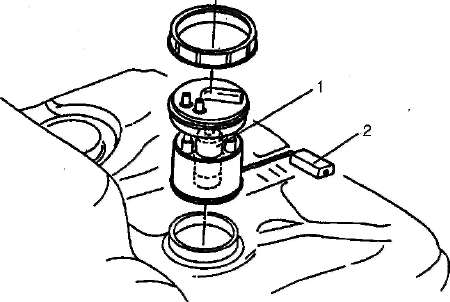

Sensor oil level (L54)

It is on

the expansion tank for the hydraulic guidance plant and VISCOMATIC (for

further details see “power

steering”). |

|||

|

|

|||

|

|||

|

|

|||

|

1. Sensor

2. Float |

|||

|

|

|||

|

This

concerns a switch (N.C), which is connected with a float, that opens it, if the level of liquid the “MIN” - value

reaches. |

|||

|

|

|||

|

|

|||

|

1. |

VISCOMATIC |

||

|

|

|||

|

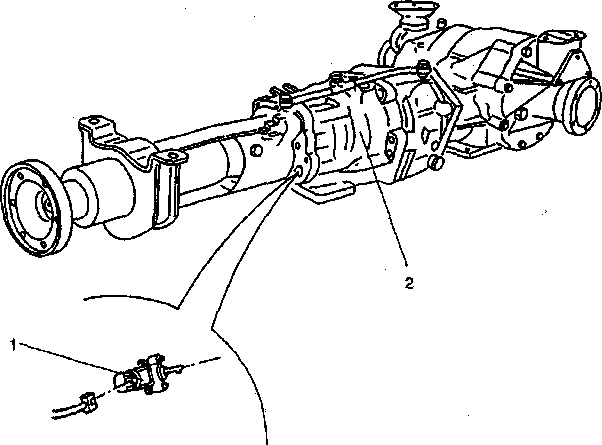

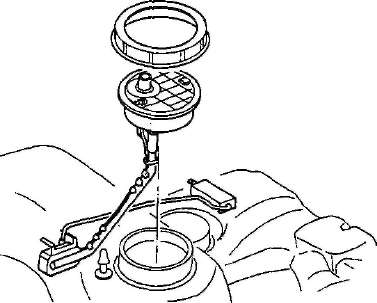

Sensor plunger lift (L55)

The

sensor is in the VISCOMATIC group and is bound with a linkage at the

pistons. This concerns potentiometer, that the steering box a signal

proportionally to the position of the piston sends (supply voltage 5V,

Rmax 2 kΩ). |

|||

|

|

|||

|

|||

|

|

|||

|

1. Sensor plunger lift

2. Group VISCOMATIC |

|||

|

|

|||

|

The

measuring of this sensor takes place automatically: Each time, if the

attitude valve at minimum value (<

900 mA) stays a certain time long, this reference value is taken as 0-Weg,

while the final stroke of the piston is accepted as maximum way

(5 mm). |

|||

|

|

|||

|

|

||||

|

VISCOMATIC |

||||

|

|

||||

|

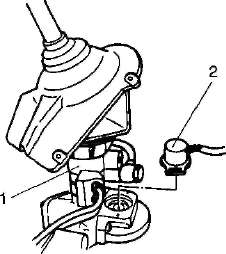

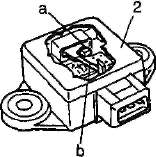

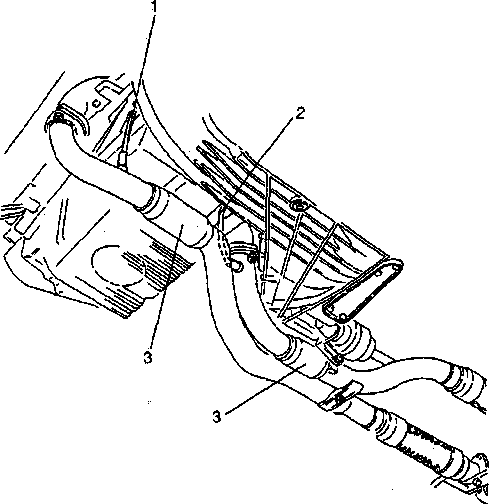

Sensor guidance angle

(L53)

This

concerns potentiometers, which is accommodated in the steering housing. It

sends a proportional signal

to the steering box to the guidance

angle (sign „+ " steering angle right, signs „- “steering angle

left).

- Supply voltage = 5 V

- Rmax = 1 kß

- Range guidance angle = 330° (+

3%)

|

||||

|

|

||||

|

1. Steering housing

2. Sensor |

||||

|

|

||||

|

Measuring of the sensor

- The vehicle with wheels on straightforward and

steering wheel position - to GUIDANCES FOR the REPAIR see

microfiche

- The sensor into the steering housing do not

build, which plugs attach.

- Attach ALFA ROMEO the TESTER to the

steering box VISCOMATIC.

- The key to trip set and with the tester examine

that the tension of the output signal of the sensor is with approx. 2,5 V: If

the tension should be approx. 0 V, that |

||||

|

|

||||

|

Element of the sensor around

180° turn. |

||||

|

|

||||

|

|

|||

|

|

||||

|

It

fastens the sensor on the steering housing, makes certain that the

steering element stands in

the position guidance center and is

the tension signal with 2.5 ± 0,04 V.

- The

correct function examined, as the steering wheel is turned and at the

right attack is kept two seconds

long, then likewise at the left attack and with the tester to examine that no error is

indicated. |

39 |

|||

|

|

||||

|

||||

|

|

|||

|

VISCOMATIC |

|||

|

|

|||

|

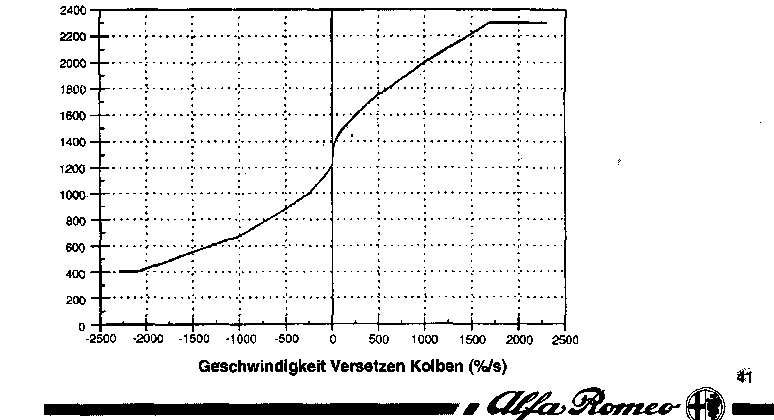

Electrical valve hydraulic control block (M25)

In the

hydraulic control block (see hydraulic control circuit) are two electrical

valves, which are steered by the

electronic steering

box. |

|||

|

|

|||

|

1. Hydraulic proportional

valve

2. Memory load valve

3. Memory |

|

||

|

|

|||

|

Memory load valve

This

concerns a valve ON/COFF that supplies the memory and holds the pressure between 82 and 95 bar, during the normal

enterprise of the vehicle.

NOTE:

The valve is only also activated

at engine number of revolutions over 400 rpm and at speeds over approx. 4 km/h. |

|||

|

|

|||

|

40 |

|||

|

|

|||

|

|

|||

|

VISCOMATIC. |

|||

|

|

|||

|

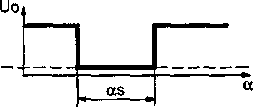

Proportional valve river

attitude

This

concerns a servo valve that a liquid

quantity proportional to the excitation stream lets flow through. In this way the

Kolbenkammer with the transfer of the piston is varied. The signal that

the steering box sends to

this electrical valve is a variable “Duty Cicle” (12 V, max. 2.3 A)

- see illustration. |

|||

|

|

|||

|

REMARK: |

With a

direct supply (12 V) the valve was damaged, therefore the system interrupts the

supply, if this tension continues

continuously longer than 100 ms. |

||

|

|

|||

|

Characteristic curve of

the valve

With a

certain river at the electrical valve one achieves a certain liquid

quantity, which the pistons from a

position to the other one transferred and so the translation about

a certain representation with

one „talk " slip to another with one „desired " slip brings, which was

calculated by the steering box.

Excitation stream (mA) |

|||

|

|

|||

|

|||

|

|

|||

|

|

|||

|

1 |

VISCOMATIC |

||

|

|

|||

|

Diagnostics of the

system

A

complex self diagnostic logic controls the complete system in each

moment:

- Supplies of the

circles of the system and the achievement circles

- Examination of the

internal memory (only with the initial test).

- Examination of the detailed signals (range

of the certified values, stages of varying and plausibility)

analogisch, as digital.

- Examination of the

control signals of the actuators.

If an

error or a disturbance is present, this information - by an appropriate

“error code” - is transmitted to the error memory (RAM) of the steering

box; at the same time the disturbance

signal lamp on on-board board lights up and the fail-safe program is

activated.

More than 70 different error

codes can be inferred!

The

disturbance signal lamp on on-board board shines for 1 -2 seconds when

starting during the initial at the

beginning of the system on {storages and internal

components).

If no

errors arise, expire them, if the controller infers against it errors,

remains the signal lamp

on.

The

fail-safe program depends on the taken error: If an error arises with a sensor, which does not affect the whole

system completely, the signal value is corrected this sensor with a reference value („Recovery

").

If

against it an important disturbance of the system is inferred, like for

example at the hydraulic system, the

system becomes cut out. If the errors in addition the achievement

circle concern scolded the steering box with the safety external switch

the system out.

All stored Fehler-die „current " as well as „the previous "

can only with the Alfa

Romeo tester to be read and

deleted.

In order

to delete and the fail-safe program switch the signal lamp off, it is

sufficient to switch the steering

box off (keys on STOP). If during restarting the errors is no longer

present, the signal lamp does not light up any longer and the fail-safe program is not activated. The

before taken up error remains nevertheless stored.

For each

error code a speedometer is intended: With the occurrence of an error this

counter is placed to its maximum

value (255): With each restart the counter is lowered around 1, if the

error is no longer present; In this way an error is cleared after 255 restarts, if it arose coincidentally

and does not occur any longer, from the memory.

Likewise the delete operation

brings all counters to Rome EO testers with the ALFA

zero, |

|||

|

|

|||

|

|

||

|

||

|

|

||

|

|

|||

|

1 |

ABS |

||

|

|

|||

|

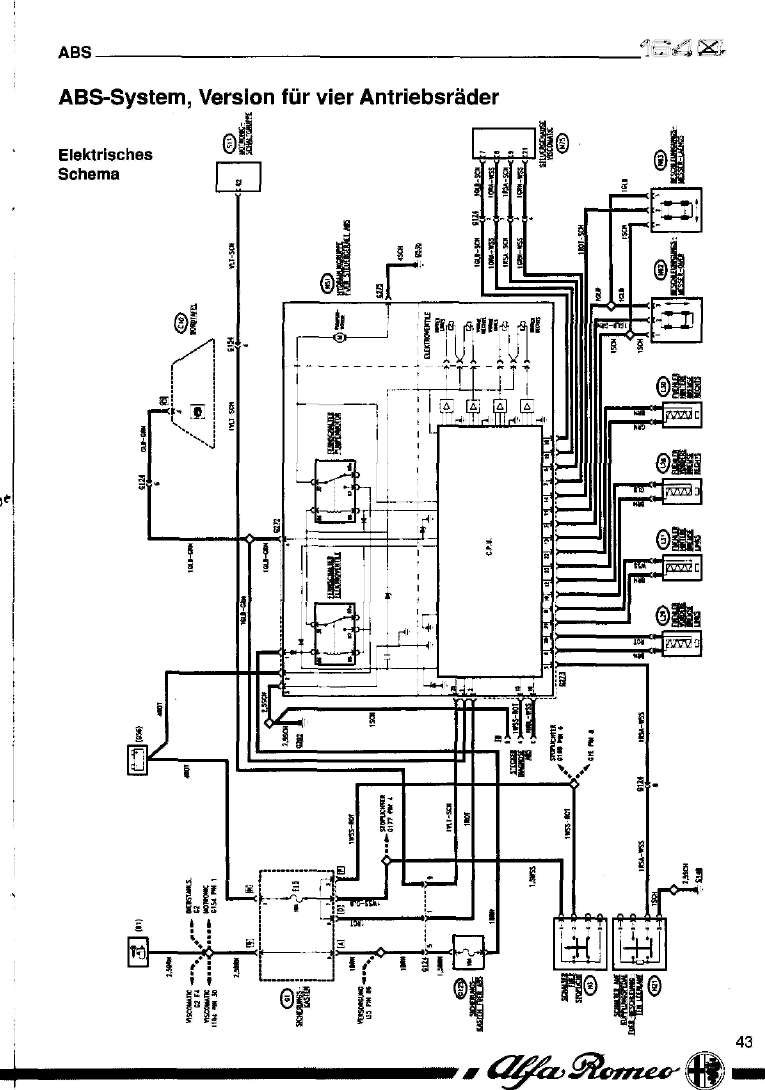

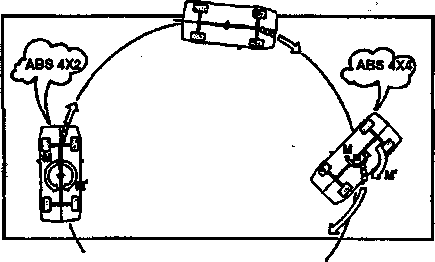

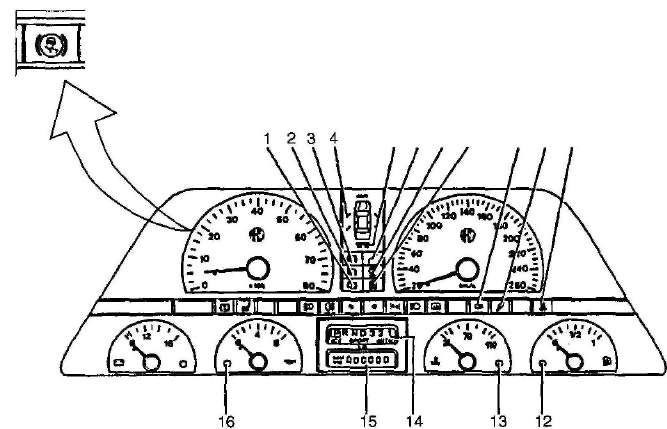

General description „ABS "

The 164 4x4 is equipped with the

electronic anti-skid system (ABS). This concerns a specific version for

this vehicle with all-wheel drive. VERSION with 6 sensors and 4

channels.

Speed sensors

The four sensors, which are

assigned at the four wheels, indicate the respective wheel speeds to the

electronic steering box - they were again designed.

Sensors of the crosswise and longitudinal

acceleration

These two sensors were added, in

order to infer additional parameters, which are needed by the specific

Kontrollogik the braking. This concerns electromechanical devices, which

are led during accelerations (+) to react and their value to the

electronic steering box.

REMARK: In the previous versions

these sensors were simple on off switches. In this case it bargains for

around hall effect sensors,

proportional signal to the taken

speed pass on: Makes possible for the operating logic to activate

different behaviors depending upon acceleration borders, while before only

one interference threshold could be considered.

Clutch switch

Makes possible the information to

the steering box over the interrupted force river between engine and

transmission, in order to be able to correct according to the braking in

this condition.

Function high-speed no-load operation (LDA)

ABS is in connection with the

MOTRON IC system. When strong decelerations the vehicle and on the basis

of high engine speeds, due to the drive system the engine would tend when

braking to turning off. The steering box ABS informs the steering box in

this case MOTRONIC. In addition the engine brake effect became effective

also at the rear wheels, which would brake more than necessarily. For the

avoidance of the over braking of the rear wheels, the logic of the system

seizes „opening of the no-load operation automatic controller

".

Signals for the VISCOMATIC system

The steering box ABS sends the 4

Geschwindigkeitssignale of the wheels to the VISCÖMAT system, which uses

these information, in order the drive logic to define (see system

VISCOMATIC). |

|||

|

|

|||

|

|

|||

|

ABS |

1J |

||

|

|

|||

|

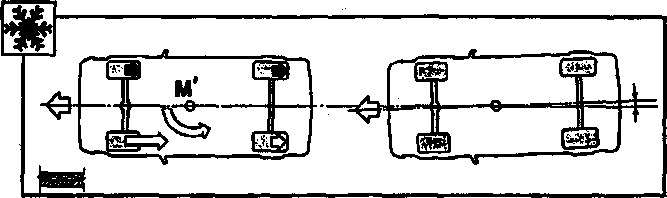

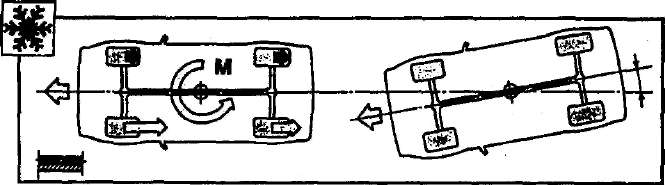

Interference logic for the version 4x4

With the special version „" the

ABS all conventional interference logics receives 4 x 4 from the brake

system, in order to prevent the blocking of the wheels.

The presence of two additional

sensors (the two accelerometers) has the development of other specific

logics for 4 x 4-Fahrzeuge “ÜÜrffl (§3* in particular made

possible.

1. Different adhesion of the wheels

In case of of different

detention condition between the right and left side of the vehicle (e.g.

layer of ice…), a different reaction at the ground at both sides arises:

From it results one M-moment, which is called „craving " and which brings

vehicle to the rotation around the point „M ". |

|||

|

|

|||

|

|||

|

|

|||

|

With vehicles with only

two drive wheels this disturbance can be reduced easily by the

conventional abs system, the brake pressure accordingly modulated and in

particular at the demanded drive wheel reduced, as well as owing to the

function „SELECT low " (clocked controls at the rear wheels). A drastic

reduction of the yaw moment makes M. possible. |

|||

|

|

|||

|

|||

|

|

|||

|

'*

€Zp&>®*me*'% |

|||

|

|

|||

|

|

||

|

With vehicles with

four drive wheels craving is

strengthened by the larger reaction of the two responsible wheels, caused in the special by the viscous drive of the

rear wheels: From this an

increase of the yaw moment M takes place in relation to the

versions with front wheel drive. |

||

|

|

||

|

||

|

|

||

|

The

specific logic of the ABS intervenes thus, as the increase of the

pressure on the wheels is affected with higher adhesion, and so the yaw

moment value M is strongly reduced. Thus driving safety of the vehicle is

improved, in the case of the different adhesion between the two sides of the

vehicle. |

||

|

|

||

|

||

|

|

||

|

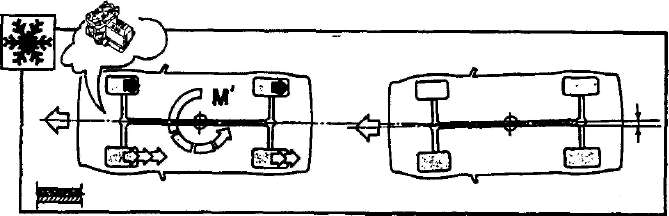

2. Curves with high speed (also with good

adhesion)

The

Kontrollogik of transverse acceleration intervenes, if the sensors infer different speed between the wheels of the two sides,

however impossible in case of a curve with high speed. The vehicle

would override, since the ABS would

lower the pressure in the two outer wheels too strongly. The reduction of

the yaw moment M would let the over-regulation effect M become

stronger, also with easy brakings. |

||

|

|

||

|

46 |

||

|

|

||

|

|

|||

|

ABS----------------------------------------------------------------------------------\

imm &u

The

sensor of transverse acceleration indicates the actual situation to

the steering box, which leads a

certain brake pressure, above all to the rear. In addition the abs

function is ahead-sent „",

which intervenes and in advance „releases the brake pressure

". |

|||

|

|

|||

|

|||

|

|

|||

|

3. Bad adhesion with acceleration

(or in the sliding

enterprise)

For

example when driving a curve out with bad adhesion all four wheels have a

certain slip. The datum speed value,

which is normally calculated, is very inaccurate and causes for one „release

effect " of the brake printing with from-following adhesion problem. This

value is thus corrected, as acceleration or slowing down of the

sensor longitudinal acceleration is measured. One reaches so a braking with limited

slip.

4. Snaps minimum number of revolutions

(high-speed no-load operation)

With

vehicles with four drive wheels, a delay of the rear wheels when

braking or when simple slowing down due to the engine brake, which brake from-following more than necessarily

„", increases. This situation

is strengthened only partially by the VISCOMATIC clutch. The clutch

remains closed in some cases „" and leads a certain torque to the rear

range (for further details see „VISCOMATIC "). With bad adhesion, this

problem solves the function „high-speed no-load operation ", which

eliminates the effect of the engine brake at the wheels. The sensor of the

longitudinal acceleration infers the

range of the slowing down and with bad adhesion (it intervenes the

ABS), sends it a signal, „from LDA ", to the steering box of the Motronic

that the number of revolutions amends

or lets the engine „more softly " to the idling speed

come.

REMARK this function

however interrupted:

- pressed clutch pedal (situation by the

appropriate switch on the clutch pedal one takes).

- Speed of the vehicle

too small

- Engine speed already

with minimum value (no-load operation) |

|||

|

|

|||

|

47 |

|||

|

|

|||

|

|

||

|

|

|||

|

|

|||

|

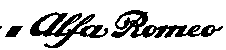

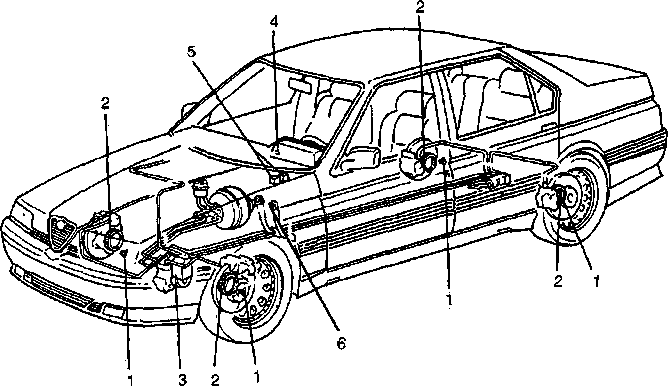

Localization components of

the system |

|||

|

|

|||

|

|||

|

|

|||

|

1.

Inductive sensors vehicle

speed 4.

2.

Clay/tone wheels 5.

3. Hydraulic group with abs

tax

housing 6. |

Control light

Sensors

along and transverse

acceleration

Switch clutch

pedal |

||

|

|

|||

|

48 |

|||

|

|

|||

|

|

|||||

|

ABS |

|||||

|

|

|||||

|

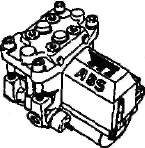

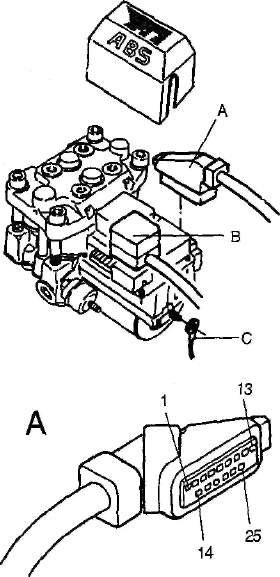

Hydraulic's group with steering box ABS

This concerns the same building

group („hybrid "), which was already installed in 164 the super. In a

block the electronic steering box with hydraulic's group and 4 electrical

control valves for the individual wheels. |

|||||

|

|

|||||

|

|

||||

|

PIN-OUT steering box; Plug „A " (G273) |

|||||

|

1 2 3 |

Signal

lamp disturbance

Switch brake pedal sensor

longitudinal acceleration |

||||

|

4. -

5. Switch clutch pedal

6. Signal rear wheel left for

VISCOMATIC

7. Signal front wheel left for

VISCOMATIC

8. Signal front wheel left

(measures)

9. Signal rear wheel left.

10.

Signal front wheel rh

(measures)

11. Supply for sensors

acceleration

12. Signal front wheel

rh.

13. Measures for sensors

acceleration

14. Sensor transverse

acceleration

15. Diagnostics line K

16. Diagnostics line L 17. --

18. Signal front wheel rh for

VISCOMATIC

19. Signal rear wheel rh for

VISCOMATIC

20. Signal front wheel

left.

21. Signal rear wheel left

(measures)

22. Signal rear wheel rh

(measures)

23. Signal rear wheel rh

24. “

25. Signal LDA to the

Motronic

PIN-OUT hydraulic's group:

Plug „B " (G272)

1. Supply (with 10 A-protection) Kl.

15

2. Direct supply of battery

3. Measures

4. Signal lamp

disturbance

Ground connection „C " (G275) |

|||||

|

|||||

|

49 |

||||

|

|||||

|

|

|||||

|

|

|||

|

ABS |

|||

|

|

|||

|

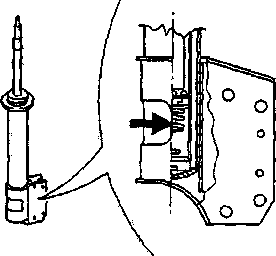

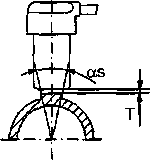

Sensors speed

The four sensors are on the hubs

of the four wheels in the range of the clay/tone wheels - 44 teeth -. The

sensors were again designed. |

|||

|

|

|||

|

|||

|

|

|||

|

Air gap value between wheel and sensor: |

|||

|

|

|||

|

Air gap for front wheels air gap

for rear wheels |

T = 0.55 - p 1.2 mm T = 0.6

f1,3mm |

||

|

|

|||

|

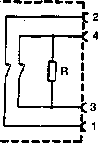

Clutch switch

This concerns a double N.C. -

Switch (closed), which opens, if the clutch pedal is pressed.

Parallel to the contact a

resistance (R = 4.22 kß) is, which serves for the examination of the

electric circuit. |

|||

|

|

|||

|

Electrical pattern

pin 1 not attached

pin 2 not attached

pin 3 measures

pin 4 signal under tension to the steering box

closed contact < 1.25 V

opened contact > 1.25 V

< 3.00 V

separated switch > 3.00 V

< 4.50 V |

|

||

|

|

|||

|

50 |

|||

|

|

|||

|

|

|||||||||

|

abs____________________________.

----------------------wmrn

m^

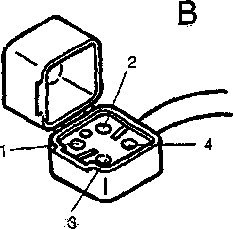

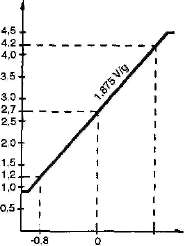

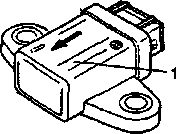

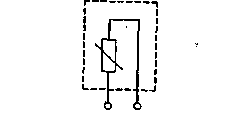

Sensors acceleration (crosswise and lengthwise)

This

concerns electromechanical devices with the principle of the

measures/feather/spring: An

acceleration moves the measures, which act against the feather/spring,

whose movement is inferred by a magnet and by an element with hall effect

is processed, which emits a tension signal corresponding for taken

acceleration. The two, sensors are under the center console, in the

proximity of the Barizentrums of the vehicle. |

|||||||||

|

|

|||||||||

|

TENSION [V] |

|||||||||

|

Electrical pattern |

+0,8 |

ACCELERATION [g] |

|||||||

|

|||||||||

|

|

|||||||||

|

pin 1 measure

to pin 2 output signal (under

tension), see diagram

pin 3 supply (5 V) |

|||||||||

|

|

|||||||||

|

REMARK: The two

sensors are calibrated in the

structure equal as well as on the same values: The steering box processes the input

values differently, which arrive

at the two pins.

TO THE

AVOIDANCE OF THE MISTAKE, CREDIT THE TWO SENSORS ON THE HOUSING DIFFERENT COLOR

MARKINGS

1.

TRANSVERSE SENSOR OF WHITE HOUSING

2. LONGITUDINAL SENSOR BLACK HOUSING

In

addition the transverse sensor has an arrow, which shows in driving

direction of the vehicle. |

|||||||||

|

|

|||||||||

|

DRIVING

DIRECTION |

|

|

||||||

|

A. Measures

b. Feather/spring

NOTE: |

|||||||||

|

The

sensors contain a magnetic element. Therefore special caution, if in the

proximity with iron-magnetic material one works. |

51 |

||||||||

|

|

|||||||||

|

|

||||||||

|

|

|||||||||

|

|

||

|

i |

||

|

|

||

|

Description of function

The

system is administered and steered by an electronic steering box, which

is positioned inside the hydraulic's group of

N51.

The

activation in the circle of the brake assembly is realized by the

hydraulic's group of N51, which control the pressure of the brake fluid

after controlling of the electronic steering box; it contains the

electrical pump as well as the four

electrical valves, one of the brake fluid with the respective

external switch for each wheel

(so-called „4 channel 'version) with respective external switch.

The

supply of the system is made directly from the battery and by ignition via

the protection of the specific

protection G125 (10A).

The four

sensors on the wheels L28, L29, L30 and L31, are connected with the steering box

and send a signal proportionally to

the speed.

The two

acceleration sensors N62 and N63, supplied at the pin 3 with

5 V and measures of the pin a 1,

supply a proportional signal for taken acceleration, which is handed over to the steering box to

the pin with 2.

By the

signal of the switch the information about an arising braking is given to

the brake H3, which steers the stop lights.

The

clutch switch H21 is directly connected with the steering box and

sends a tension signal, which informs

engine and transmission about the separation. The steering box is

connected (pin 25) with the Motronicsteuergerät S11, to which the

demand is given to the

accelerated minimum number of revolutions

(LDA).

LDA = idling speed rise =

high-speed no-load operation.

In addition a connection with

the controller N75 Viscomatic exists for the

transmission

the Geschwindigkeitssignale

of the four wheels.

The

internal self diagnostic system in the steering box announces disturbances

or not correct function over pin 1 to

the appropriate signal lamp of on-board board C10; the same

signal is announced also to errors

in the hydraulic's group - pin 4 of the plug G272

-. |

||

|

|

||

|

|

|||

|

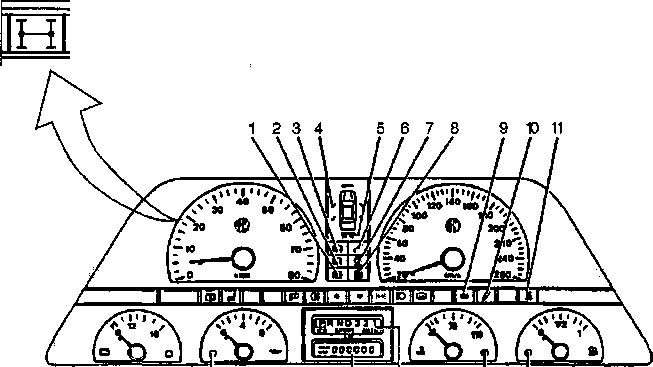

abs_____________________________________________jiöö

m

Same diagnosis

The

available version of the ABS excludes the normal brake system from the

Selbstdiagnose, which holds continuously all components and parameters of

the system under control: in case of of disturbances or bad function

scolded yourself the system automatically out and only the conventional mechanical

servo-supported system is active. This situation is indicated to the

driver by an appropriate signal lamp of on-board board. The signal lamp „disturbance ABS " is

activated with switched on ignition - its expiring secures that the initial test test of the

system was positive and is

present no

disturbances. |

|||

|

|

|||

5 6 7 8

9 10 11 |

|||

|

|

|||

|

53 |

|||

|

|

|||

|

|

||

|

|

|||

|

|

||

|

1B^L

GH___________________________________________MOTRONIC M 3.7

Electronic engine management Motronic M 3.7

A new electronic engine

management steers and supervises all parameters of the engine,

optimizes achievement and consumption by fast responding in the

different operating conditions.

This concerns the version M

3,7 of the examined and reliable system BOSCH

MOTRONIC. |

||

|

|

||

|

54 |

||

|

|

||

|

|

||

|

||

|

|

||

|

Oil |

||

|

|

||

|

|

||

|

||

|

|

||

|

|

||

|

||

|

|

||

|

|

|||

|

1 |

MOTRONIC M

3.7 |

||

|

|

|||

|

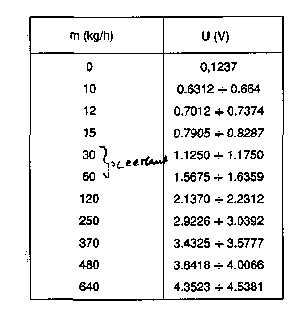

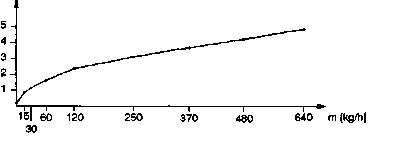

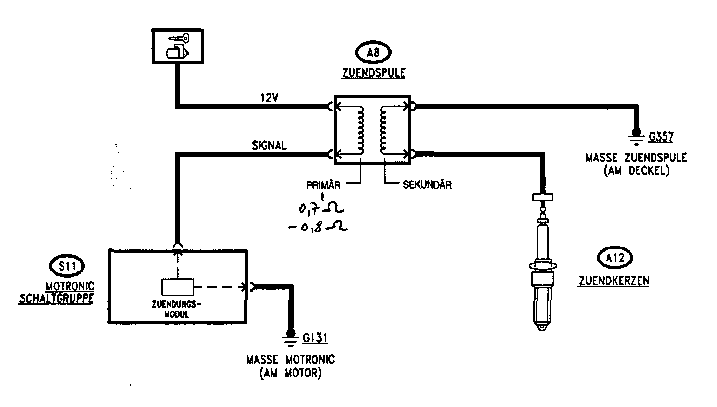

MOTRONIC M 3.7

The new

Motronicsystem M 3,7 equipped

with a controller of the newest technological development.

The

electronic ignition with „static distribution " was changed, with one coil

each for each spark plug (MONO COIL); in addition the achievement modules

are contained inside the steering box; this solution eliminates the

external ignition circle, and increases thus the reliability and the

security of the ignition system.

With this

version M 3,7 a phase injection (sequential) for each cylinder was realized. The injection moment is not

alike to no more for all cylinders, for each cylinder takes place

this at the optimal point of

injection, which is calculated by the steering box, depending upon

load, number of revolutions and

engine temperature.

REMARK:

The

moment planned in the calculation is the injection, from which the duration of injection is calculated. This

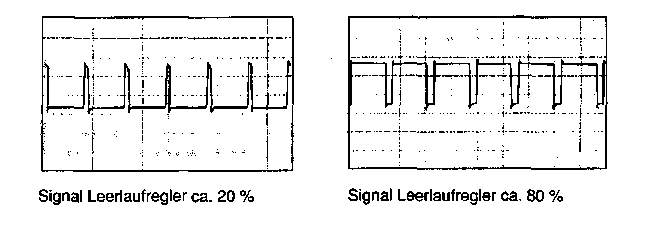

is the thermodynamic point and its correct control makes possible a still more exact